- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

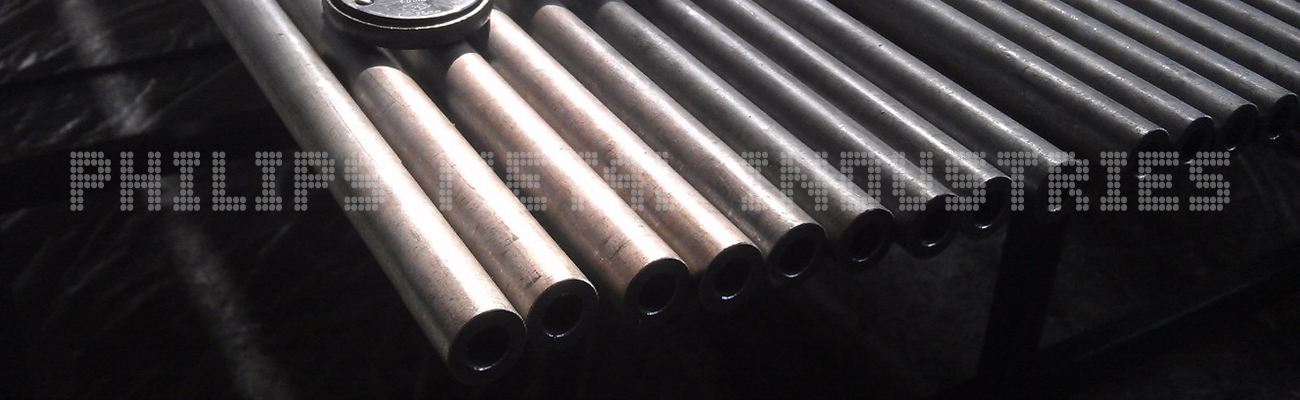

Philips Metal is one of the renowned manufacturer, exporter, stockist, stock holder and supplier of a qualitative range of Stainless Steel 304L Condenser Tubes that are being designed as per the national and international standard quality of raw materials.

A number of tests illustrating the corrosion resistance of Stainless Steel 304L Seamless Condenser Tubes in a variety of chloride containing environments are being reviewed in terms of pitting, crevice corrosion and stress corrosion cracking. The surface hardness is also high which gives this grade of SS 304L Condenser Tubes a better resistance to certain types of erosion. The high strength and surface hardness are consequences of the high nitrogen content of SS 304L Seamless Condenser Tubes.

Meanwhile, our 304L Condenser Tubes are available in different size, thickness & specification as per the requirements of our esteemed clients.

| Range : | 6 mm OD to 219.1 mm OD |

| Thickness : | 0.7 mm Thick To12.7 mm Thick |

| Length : | Tube Length - 1 Mtr Upto 32 Mtrs Long / U-Tube Length – 32 Mtrs U Tube Coil – 50 Mtrs |

| Specifications : | ASTM A249 / SA249 |

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

|---|---|---|---|---|---|---|---|

| SS 304 | S30400 | 1.4301 | Z7CN18‐09 | X5CrNi18-10 | SUS 304 | 304S31 | 08Х18Н10 |

| SS 304L | S30403 | 1.4306/1.4307 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 304S11 | 03Х18Н11 |

| SS 304H | S30409 | 1.4301 | - | - | - | - | - |

| C | Mn | Si | P | S | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.07max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 | min: 8.0 max: 10.5 | — |

| 304L | 0.03max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 | min: 8.0 max: 12.0 | 0.10 max |

| 304H | min: 18.0 max:20.0 |

min: 8.0 max: 10.5 |

min: 0.04 max:0.10 |

0.75 max |

2.0 max |

0.045 max |

0.03 max |

0.10 max |

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 304 | 75 | 30 | 40 | 201 | 92 |

| 304L | 70 | 25 | 40 | 201 | 92 |

| 304H | 75 | 30 | 40 | 201 | 92 |

| SS 304/304L | ||||||

|---|---|---|---|---|---|---|

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

| at 68°F: 0.285 | 9.4 at 212°F | 28.3 at 68°F | 28 | 9.4 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500 to 2590 |

| 12.4 at 932 °F | 39.4 at 752°F | 10.2 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 10.4 at 32 – 1500°F | |||||

| SS 304H | ||||||

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | ||

| at 68 °F | at 68 – 212°F | at 68 – 1600°F | at 212°F | at 932°F | at 32 – 212°F | in tension (E) |

| 0.285 | 9.2 | 11.0 | 9.4 | 12.4 | 0.12 | 29 x 106 |

| Stainless Steel 304L Condenser Tubes | Stainless Steel 304L Seamless Condenser Tubes |

| SS 304L Condenser Tubes | SS 304L Seamless Condenser Tubes |

| Condenser Tubes | SS 304L JIS Condenser Tubes |

| SS 304L DIN Condenser Tubes | ASME Stainless Steel 304L Condenser Tubes |

| ASTM A 249 Stainless Steel 304L Condenser Tubes | ASTM A 249 SS 304L Seamless Condenser Tubes |

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

ss pipes exporter, jindal ss 304 pipes price list, stainless steel 304 instrumentation tube, stainless steel pipe aisi 304, stainless steel 304 pipe thickness, 304 stainless steel pipe weight per foot, ss tubes supplier, jindal stainless steel 304 pipe price, ss tubing manufacturer, stainless steel 304h welded pipe exporter in india, stainless steel 304 tube pipe, 304l stainless steel tubing distributor, stainless steel 304h pipe manufacturer, 304 stainless steel pipe cost, stainless steel 304 pipe sizes, stainless steel 304l erw tube, 304l stainless steel pipe schedule, stainless steel 304 efw pipe manufactures in mumbai, ss 304h welded tube, ss 304 pipe price per kg in india, 304l schedule 10 stainless steel pipe, stainless steel 304 tube sizes, ss 304 tube price, ss 304l erw pipe, stainless steel pipe 304 grade weight per meter, ss 304h seamless pipes, stainless steel 304 pipe manufacturers india, stainless steel 304 pipe weight per meter, 304l stainless steel pipe dimensions , 304l stainless steel pipe pressure rating, 304 stainless steel rectangular tubes stockist , stainless steel 304 pipe schedule, stainless steel 304 pipe weight, stainless steel 304 pipe price per kg in india, stainless steel 304 square tube, stainless steel 304 seamless tubes, stainless steel pipe 304 grade, stainless steel 304 tube suppliers, 304 stainless steel tube specifications, stainless steel 304h seamless tube.